Structures or Why things don’t fall down - Book Summary Notes

- Structures Insider

- Oct 16, 2021

- 7 min read

Updated: Feb 12, 2022

Here we have the conversation in the unbuttoned mood of a learned engineer with wide sympathies about his art, its history, its range, and the silly things which happen. It reads easily and has immense charm.--Architect's Journal

It is really, really good if you want a primer on the structural design.--Elon Musk

Rich and readable...personal, witty, and ironic.--Scientific American

CHAPTER 1: The structures in our lives

p18. Can engineers learn from natural structures? What can doctors and biologists and artists and archaeologists learn from engineers?

p20. (the living structure) Trees are the most durable living structures (max height of 110 meters)

p22.(the technological structure) Limitation of material resources made the engineer turn to technology which was the primary approach to solving this problem.

p23. Pneumatic tire: (John Boyd Dunlop) A pneumatic, or air-filled, the tire is made of an airtight inner core filled with pressurized air. A tread, usually reinforced with steel belting or other materials, covers this inner core and provides the contact area with the road. John Boyd Dunlop

p25. (structures and aesthetics) relating the appearance to the structure of their products.

CHAPTER 2: Why structures carry a load

p38. All materials and structures deflect, although to greatly varying extents, when they are loaded.

CHAPTER 3: The invention of stress and strain

p50. Hooke's law: properties of material & behavior of the structure.

p52. E= Youngs Modulus = elastic modulus = stiffness - fundamental knowledge of stress and strain

p55-56. The strength of a Structure is simply the load (N or kg) that will just break the structure. Known as breaking load.

Strength of Material: is the stress (MN/m2) required to break a piece of the material itself.

The object of many strength calculations is to predict the strength of a structure from the known strength of its material.

CHAPTER 4: Designing for safety

p66. Stress trajectories in a bar are uniformly loaded in tension with and without a crack.

p68. Stress at the tip of the crack may well be a hundred or even a thousand times higher than the stress elsewhere in the material.

CHAPTER 5: Strain energy and modern fracture mechanics

p71. Information about local vs breaking stress

p74. Every elastic material which is under stress contains strain energy, and it does not make much difference whether the stress is tensile or compressive.

p92. The commonest arrangement to absorb energy is bending.

To break any material in tension a crack must spread right across it.

p94. The quantity of energy required to break a given cross-section of a material defines its toughness - fracture energy.

CHAPTER 7: Joints, fastenings, and people

P132-147 important pages.

p133. The design of a structure is influenced much more by its stiffness than by its strength. Where the need is for rigidity rather than strength, the whole problem becomes very much easier and cheaper.

p148. Creep : [definition] is why old shoes are more highly stressed than new ones.

CHAPTER 8: Soft materials and living structures

p151. emulsion [definition] : Two liquids can form different types of emulsions. An emulsion is a mixture of two or more liquids that are normally immiscible (unmixable or unblendable).

p156. Arteries are under constant stress n strain.

p158. In a cylindrical vessel (always) :

longitudinal stress: p

Circumferential stress: 2p

p159. Poisson ration [definition] : elastic effect behavior.

p161. Membranes stretch with no thickness deformation: constant stress.

p171. Our ancestors generally avoided tension structures as far as they could and tried to use constructions in which everything was in compression.

p174. What kept a building from tipping up and collapsing was not so much strength of the stones and mortar as the weight of the material acting in the right places.

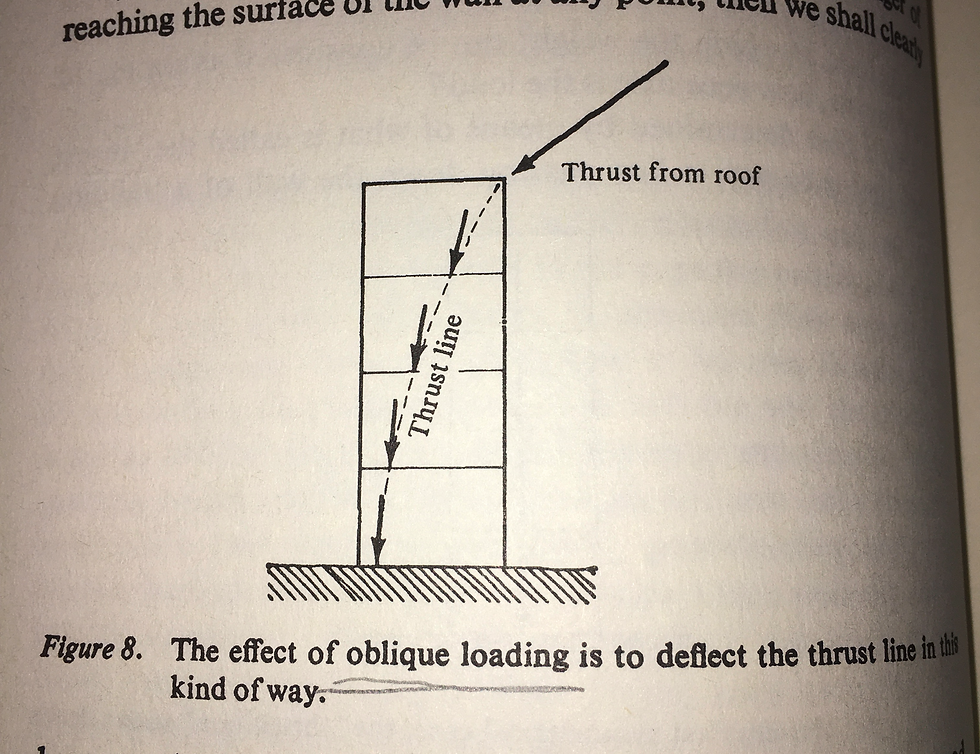

p181-183. Thrust line: The line of thrust is the locus of the points, through which forces pass in a retaining wall or an arch. It is the line, along which internal forces flow.

In a stone structure, the line of thrust is a theoretical line that through the structure represents the path of the resultants of the compressive forces. For a structure to be stable, the line of thrust must lie entirely inside the structure

p182. Oblique loading [definition]: the loading that deflects the thrust line in this kind of way.

p184. Where there is a crack, there must once have been tension stress.

walls, masonry dams usually fail not from lack of strength but from lack of stability.

p186. Heavy masonry can be regarded as a structure that is ‘ pre-stressed’ conditions.

p188. Definition of an Arch.

p188-191. Useful information about arches.

p192. Sealing up of structures (interesting to read)

The square-cube law (or cube–square law) is a mathematical principle, applied in a variety of scientific fields, which describes the relationship between the volume and the surface area as a shape's size increases or decreases. It was first described in 1638 by Galileo Galilei in his Two New Sciences as the "...ratio of two volumes is greater than the ratio of their surfaces”.

-unlike most other structures, buildings fail because they become unstable and tip-up.

CHAPTER 10: Something about bridges

p200. The facts of life are that the rise of the arch must be about half its span.

p201. Cast iron is very brittle. It resembles stone in being strong in compression but weak and unreliable in tension, and so, in building construction, it has to be treated rather like masonry.

p202. Vibrations of the trains would crack the brittle cast iron.

p205. James Finlay: James Finlayson was a Scottish Quaker who, in effect, brought the Industrial Revolution to Tampere, Finland.

p206. The cables of a suspension bridge take up the best shape automatically because a flexible rope has no choice but to comply with the resultant of all the loads which are pulling on it.

p225. After all, how many house architects even talk to a naval architect?

p231. A cantilever: ships masts, turbine blades, horns, teeth, animals necks, and trees

p238. A cantilever truss will probably break mear its roots

p239. Animal skeleton - shear bracing

p242. Longitudinal stress increases as you move away from the neutral axis

p245. Shear stress measures the tendency for one part of a solid to slide past the next bit or jerk the rug from under someone's feet or ankle twist.

p249. A trellis (treillage) is an architectural structure, usually made from an open framework or lattice of interwoven or intersecting pieces of wood, bamboo, or metal that are normally made to support and display climbing plants, especially shrubs.t 5

p255. System of Applied Tension: in other words, by lacing.

p256. Plastic propellers

p257. Shear stress is only tension and compression acting at 45 degrees and vice versa.

p258. In ductile materials both tension and compression, failure tends to occur by shear. (look diagrams above)

p260. The wings of an aircraft are subject to bending forces, very much like a bridge.

p264. Twisting or torsional deflection.

p266. Torsional stiffness = no twist.

p269. Torsion & twisting.

p271. Torsion makes everything heavier on a design. (skiing=torsion)

p272. Blackhole = massive compression force.

p273. Compression = study of ways of getting out of tight places.

p274. Compressive failure == 45degree shearing.

p275. Brittle = has cracks.

p277. Ductile failure in metals would be the same in compression and tension( by shearing).

p280. Columns = trees (good columns in compression)

p281. Pre-stressed tree in a calm..the outside of the trunk is in tension all around, the inside is in compression.

p283. Keep concrete always in compression and don't allow it to go to tension when bending occurs, therefore no cracking in concrete is happening in pre-stressed beams.

p293. Long-wave mode: buckle over all of its lengths, or short-wave: that is to say locally, by putting a sort of crease or crumple onto the wall of the tube.

p294. Bamboo is a natural stiffener that uses stringers or ribs to stiffen up.

P296 - 297.

A sandwich-structured composite is a special class of composite materials that is fabricated by attaching two thin but stiff skins to a lightweight but thick core. The core material is normally low strength material, but its higher thickness provides the sandwich composite with high bending stiffness with overall low density.

Open- and closed-cell-structured foams like polyethersulfone polyvinylchloride, and honeycombs are commonly used core materials. Sometimes, the honeycomb structure is filled with other foams for added strength.

p303. “concept of design”

p305. The cross-section of a tension bar is proportional to the load.

p306. “ work of fracture falls dramatically with the increase of tensile strength”

p310. Compound interest effect: Compounding: is the process in which an asset's earnings, from either capital gains or interest, are reinvested to generate additional earnings over time. This growth, calculated using exponential functions, occurs because the investment will generate earnings from both its initial principal and the accumulated earnings from preceding periods.

p311. Meccano is a model construction system created in 1898 by Frank Hornby in Liverpool, United Kingdom. The system consists of reusable metal strips, plates, angle girders, wheels, axles and gears, and plastic parts that are connected using nuts and bolts. It enables the building of working models and mechanical devices.

Monocoque: an aircraft or vehicle structure in which the chassis is integral with the body.

p315. Dracone barge (photo above)

p319. Energy intensity is a measure of the energy inefficiency of an economy. It is calculated as units of energy per unit of GDP.

p321. E/p that is to say, the specific Youngs modulus which governs the weight-cost of the overall deflection. - Read Appendix 4.

p324-325. Meaning of engineer: ‘the entire physical world is most properly regarded as a great energy system “

p330. A great deal of the strength-predicting elements of design boils down to a sort of game in which we try to spot the weakest link in a load-bearing system.

p333. [definition] Fatigue = fluctuating loads.

p337. Fuselage [picture below]

p350. Interesting read about aerodynamics

p355. Architecture vs civil engineer ( efficiency vs aesthetics )

p359. Emotional with the design - subconscious mind - the imprint of the character.

p364. Philistinism engineers are all about: In the fields of philosophy and æsthetics, the derogatory term philistinism describes the 'manners, habits, and character' of a person whose anti-intellectual social attitude undervalues and despises art and beauty, spirituality and intellect.

p366 - 367. “ modern technology gets more and more functional, we can less and less bear to look at it.” “ an ugly ship is no more attractive than an ugly woman - however fast she may be”

p369. Doric architecture: The Doric order is characterized by a plain, unadorned column capital and a column that rests directly on the stylobate of the temple without a base.

The Doric entablature includes a frieze composed of triglyphs—vertical plaques with three divisions—and metopes

Appendix A - the process of design.

You can get the book here:

*Affiliate links included